Science and Sustainability: Is 3D Printing the Answer?

Fashion and 3D technology are converging, and many are betting that it will reshape the future of fashion. Let’s dig in.

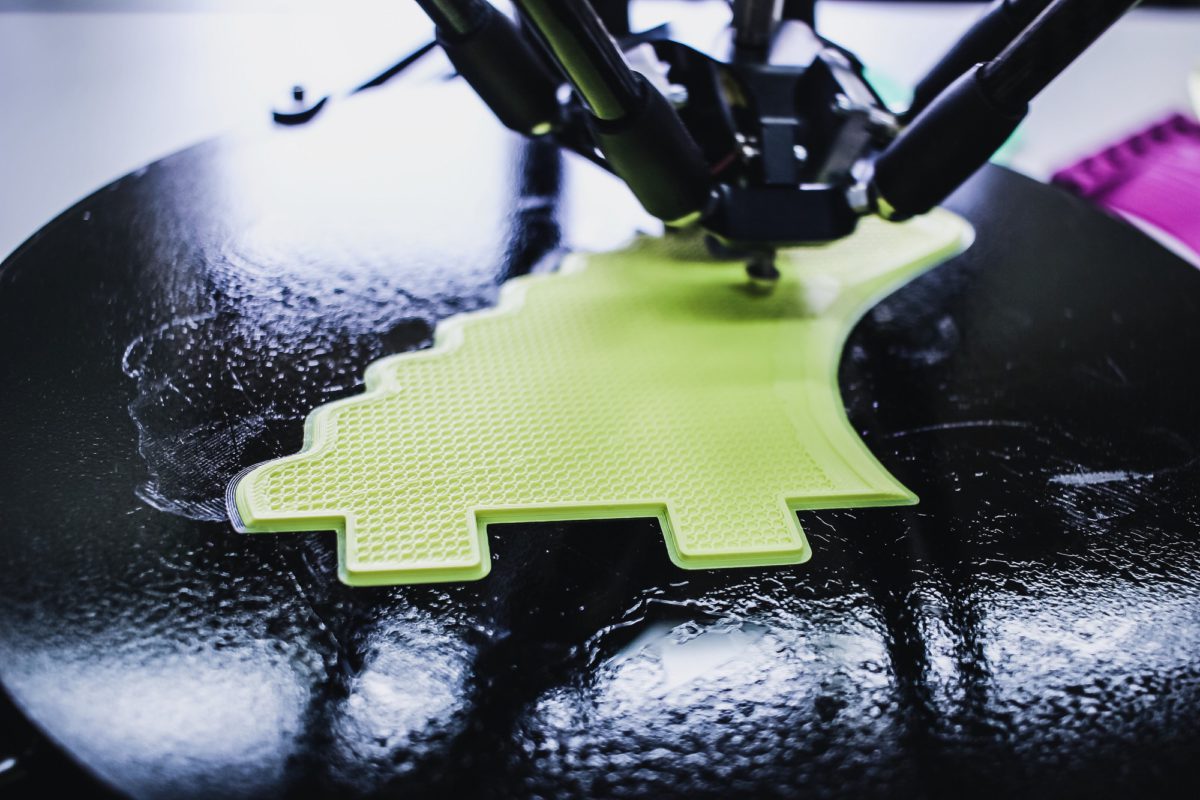

To make a product today, a clothing or footwear designer forms a mould and fills that shape to produce the item. 3D technology is the opposite: known as “additive manufacturing,” this approach allows designers to make garments without ever carving out a form. Instead, layers of material are superimposed according to a digital design to create something new. Such technology has the potential to cut down the industry’s wasteful and polluting practices. Let’s dive into the benefits and risks of this pioneering engineering.

No more cut-offs and scrap

According to a report published by the Global Fashion Agenda and Boston Consulting Group, pre-consumer waste accounts for 35% of raw materials in the supply chain. 3D technology generates less waste than traditional manufacturing processes as they require only a specific amount of material to create a product. This removes the uncertainty behind the quantity or volume of resources needed for assembly. Clothing company Son of a Tailor recently launched a “made-to-order” pullover campaign using 3D-knit technology. The collection eliminates 99.9% of material cut-offs when compared to industry standards – an unprecedented milestone to combat waste.[1]

Easing emissions & saving raw materials

The fashion industry is responsible for 10% of annual global carbon emissions. This amounts to more than all international flights and maritime shipping combined each year.[2] 3D printing could save up to 90% of natural resources needed for manufacturing apparel, says a recent study by the European Commission. Instead of extracting raw materials from the earth, 3D technology can use recyclable waste, such as discarded plastic, to make new products. For example, the American brand Ministry of Supply diverted 1.2 million water bottles from landfills and transformed them into 3D filaments. This saved the company from releasing 21 tonnes of CO2 into the atmosphere, equivalent to driving around the planet in a medium-sized sedan – twice!

What are the cons?

3D printing is (still) not without fault. The technology can leave a trail of toxic by-products that require complex hazardous waste management. This includes handling volatile organic compounds that can vaporize at room temperature, adversely affecting air quality and human health.[3] Even so, the rising potential of 3D technology to help the fashion industry champion greener practices remains optimistic. Let’s see who rises to the challenge and accelerates this progress.

References

[1] “How Is 3D Printing a Sustainable Manufacturing Method?” | Azo Material. Available at: https://www.azom.com/article.aspx?ArticleID=20017

[2] “How Much Do Our Wardrobes Cost to the Environment?” | The World Bank. Available at: https://www.worldbank.org/en/news/feature/2019/09/23/costo-moda-medio-ambiente

[3] “The Hazards of 3d Printing and the Necessary Ppe for Protection.” | International Enviroguard. Available at: https://int-enviroguard.com/blog/the-hazards-of-3d-printing-and-the-necessary-ppe-for-protection/

Author: Naomy Gmyrek

Latest from the Blog