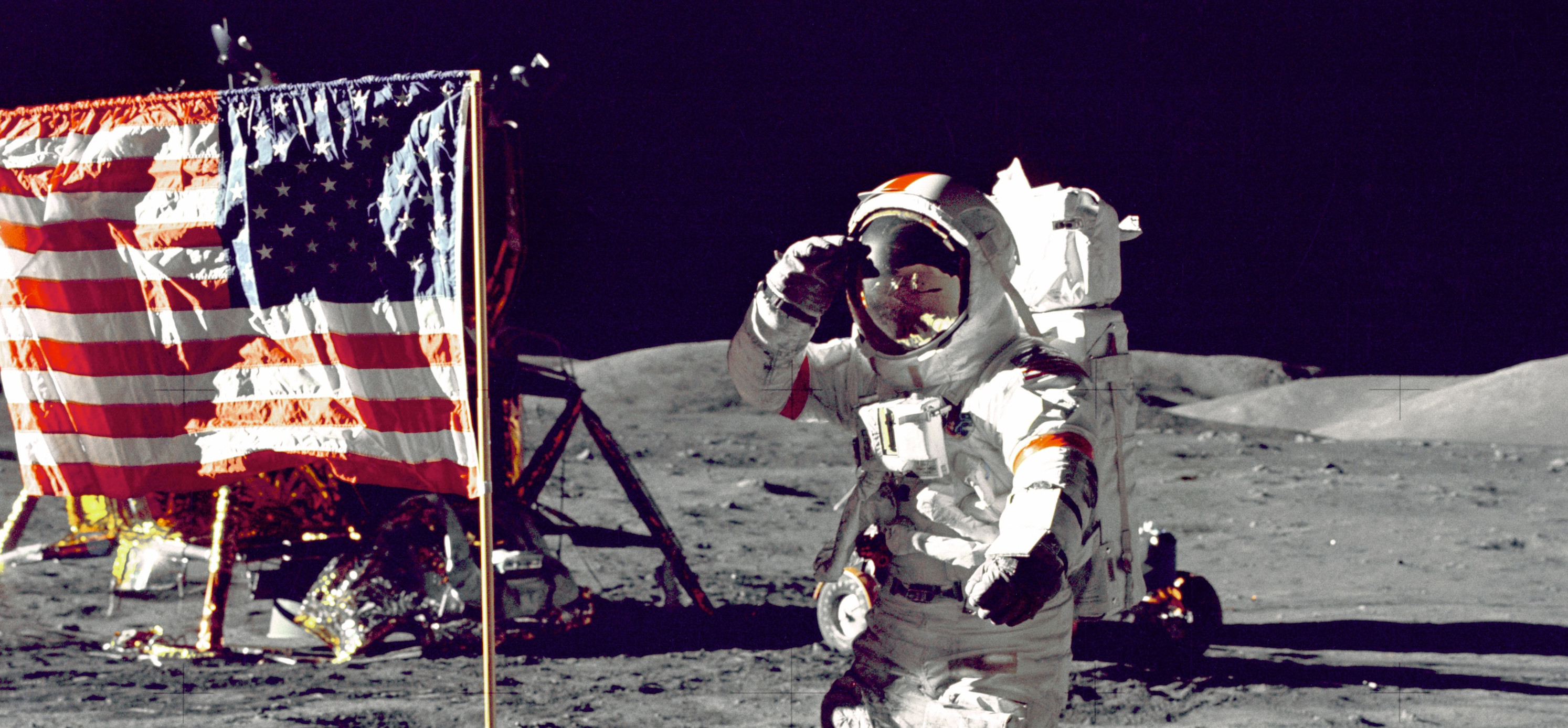

Why are you still using nylon made from oil?

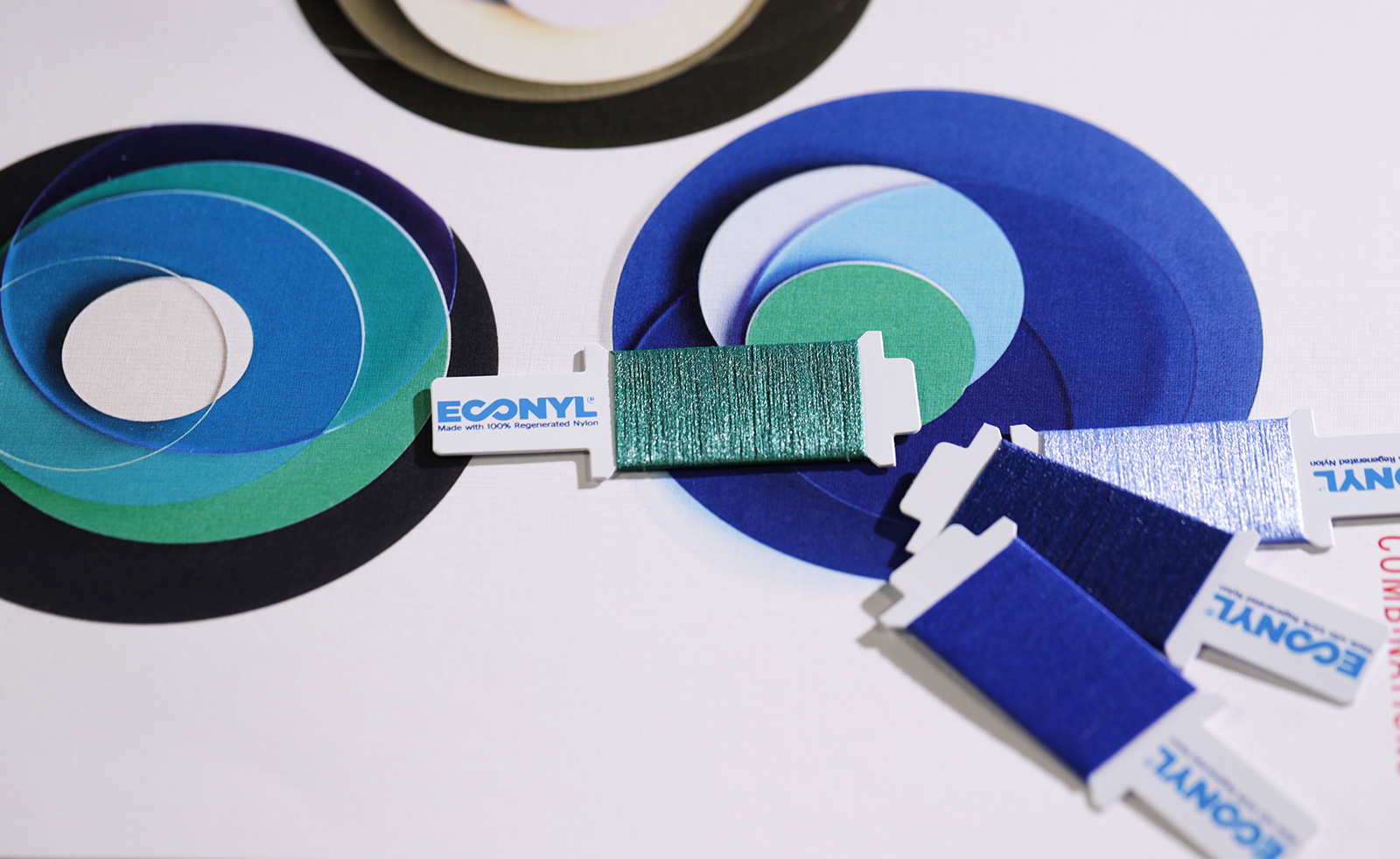

Made from waste like fishing nets and old carpets, ECONYL® regenerated nylon is transforming the flooring, furniture, automotive and fashion industries.

Explore the ECONYL® productsTHE PROBLEM

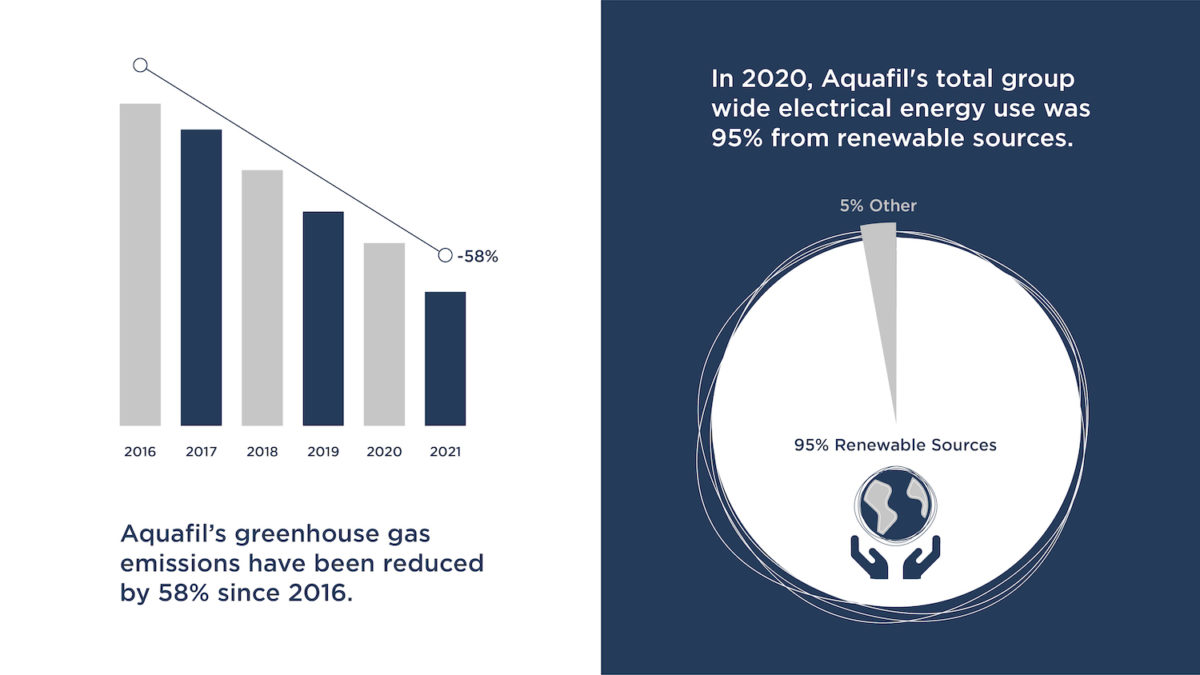

Our planet is growing hotter and hotter by the year. The extraction and processing of natural resources currently accounts for one half of total greenhouse gas emissions worldwide. Meanwhile, abandoned waste in landfills is burned in open fires, contributing to nearly 5% of global greenhouse gas emissions.Whether it's interior design, fashion or automotive, we’re designing products that deplete natural resources and create waste in the process. But it doesn’t have to be this way.

THE SOLUTION

Design sits prominently at the heart of the solution. Designers can influence the product environmental footprint with their early design decisions by choosing sustainable ingredients that are recycled and recyclable.Further, design is also at the heart of the circular economy. It’s calculated that by applying circular strategies to just five of the most common materials in our economy – cement, aluminum, steel, plastic and food – we can eliminate 9.3 billion tonnes of CO2 by 2050. We can help!

How we work

Designers & Architects

Specify products made with ECONYL® nylon to create beautiful contracts, hospitality and residential spaces while earning LEED credits.

Manufacturers

Automotive Manufacturers

Waste Collectors & Municipalities

“Designers, they have control of what raw materials they will use, how the products will be manufactured, how the product or material will be used, how it will perform.”

“With 127 products now C2C Certified, the widespread use of ECONYL®, ecoBack, our well-established CO2RE initiative, membership of the Healthy Seas® programme and partnership in the CARE carpet recovery scheme, we now rank as carpet tile manufacturer with serious answers to today’s sustainability challenges. We’re finding more and more designers coming to us not simply because of our style or performance, but our sustainable actions too.”

"The introduction of ECONYL® in our collections is an example of how innovation and new products can be eco-sustainable".

"With the help of ECONYL® nylon, we’ve built noho move™, the most transformational chair in the history of residential furniture.”

“Since we began this journey with Aquafil we have been able to reduce the carbon footprint of our finished product by close to 70%. The biggest portion of that is the work we have done to get 100% recycled nylon into products”.

OUR STORY OF CIRCULARITY

OUR SUSTAINABILITY STORY