Achieve High Performance and Durability with ECONYL® Nylon

Nylon has been prevalent in design since nylon hosiery rose to fame in the 1940s and eventually expanded into the rest of the fashion industry, interior design, automotive manufacturing and beyond. Its strength and durability matched with its ability to be stretched and molded into shape has made nylon an extremely useful and popular ingredient.

However, standard nylon can come at a pretty high price for the environment. It is typically derived from extracted oil, requires a large amount of energy and water to create and ends up spending a lifetime in landfills as a non-biodegradable material.

An alternative solution is ECONYL® nylon: a 100% regenerated nylon that is kinder to the planet without sacrificing performance or durability.

More Than Recycled: The Environmental Impact of ECONYL® Nylon

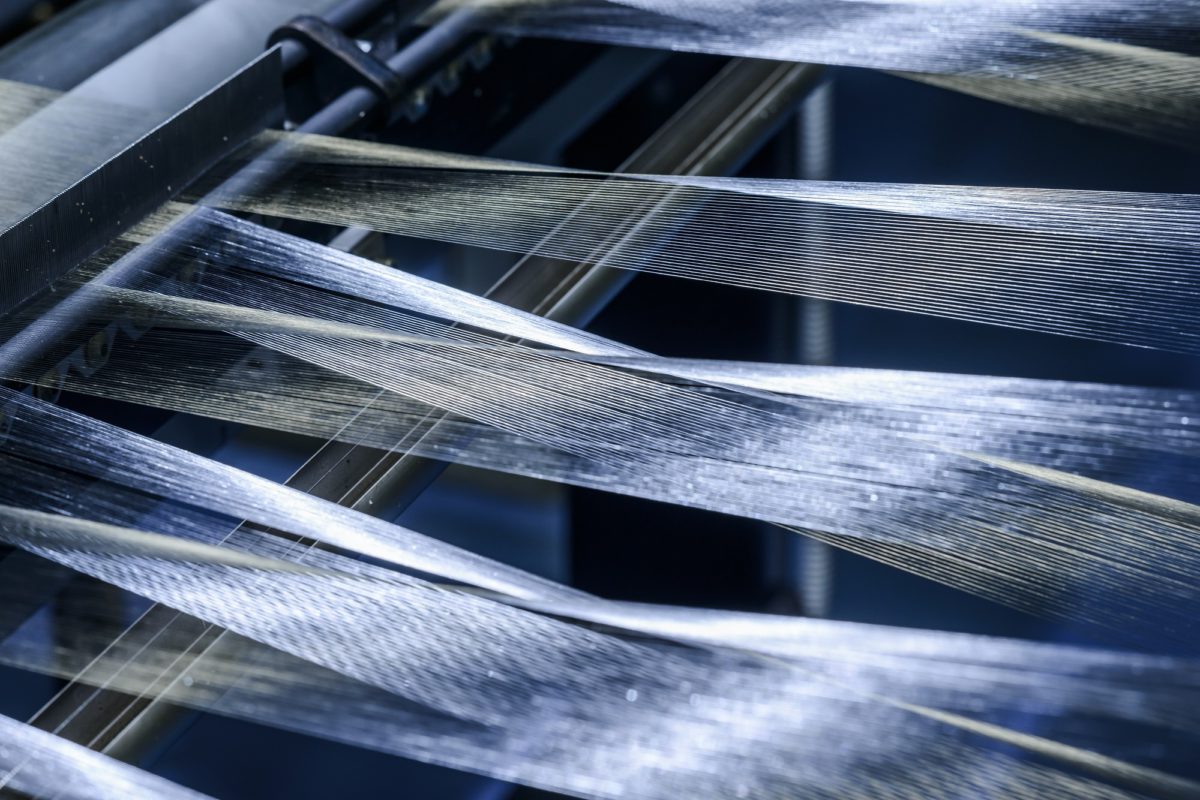

ECONYL® nylon is so much more than a recycled product, but it does start with recycling. We go to extraordinary lengths to collect and recycle nylon waste, including carpets, discarded fishing nets and fabric scraps. The nylon waste is then depolymerized back into its raw material, caprolactam. By taking the nylon back to caprolactam, we have the ability to then polymerize that regenerated caprolactam into nylon for our customers to create new products.

For every 10,000 tons of ECONYL® raw materials that are created, 65,100 tons of CO2 emissions are avoided and 70,000 barrels of crude oil are saved. Using ECONYL® nylon has the potential to reduce the global warming impact of nylon by up to 90% compared with the material generated from oil. The nylon is produced in a facility that is powered by 100% renewable energy sources, including hydroelectric and wind.

In addition to these environmental benefits, ECONYL® nylon is also produced with human health and safety in mind. The ECONYL® Regeneration System was engineered to avoid the use of solvents typically found in chemical recycling. We reduced Scope 1 + Scope 2 carbon emissions by 64% in five years and continue to closely monitor the quality of our wastewater to minimize the impact of our industrial activities.

The Same Performance and Durability You Expect from Nylon

Designers are often hesitant to use a recycled material, let alone a regenerated one, in the fear that it will be lower quality than the original material. Customers who work with ECONYL® nylon are often pleasantly surprised to find that it is chemically identical to nylon sourced from oil and has the exact same performance characteristics with no degradation of durability and performance. There is no downgrade in quality when using it.

ECONYL® nylon is not only 100% regenerated, but is also infinitely regenerable to continue creating like-new nylon with the same quality and performance. The solution-dyed yarn is bleach and fade resistant and the cationic polymerization provides inherent stain protection. The ECONYL® Global Collection also uses a fiber cross section modification ratio of 1.8 for advanced soil release and improved texture retention and wear resistance.

Milliken’s Coastline Collection

Benefits of Using ECONYL® Nylon

There are opportunities for ECONYL® nylon to be used in any product where nylon 6 is used today: as a fiber in apparel, carpets, and industrial ropes and cables, as an engineered polymer in sunglasses or automotive interiors, or as a filament in furniture or 3D printing. From sportswear and swimwear to interior and automotive design, markets around the globe are finding value in ECONYL® nylon as a high performance nylon with significantly lower embodied carbon than its oil-sourced counterpart.

The regenerative properties of ECONYL® nylon empower designers to reimagine their creative process by designing with the end in mind. We urge designers to not only consider how they can replace their current materials with recycled and regenerated ingredients, but also how they can create products that are easily dismantled and reused at their end of life – all at the same high quality.

The opportunities for innovation and creativity are genuinely infinite with ECONYL® nylon.

Author: Ian Burt

Latest from the Blog